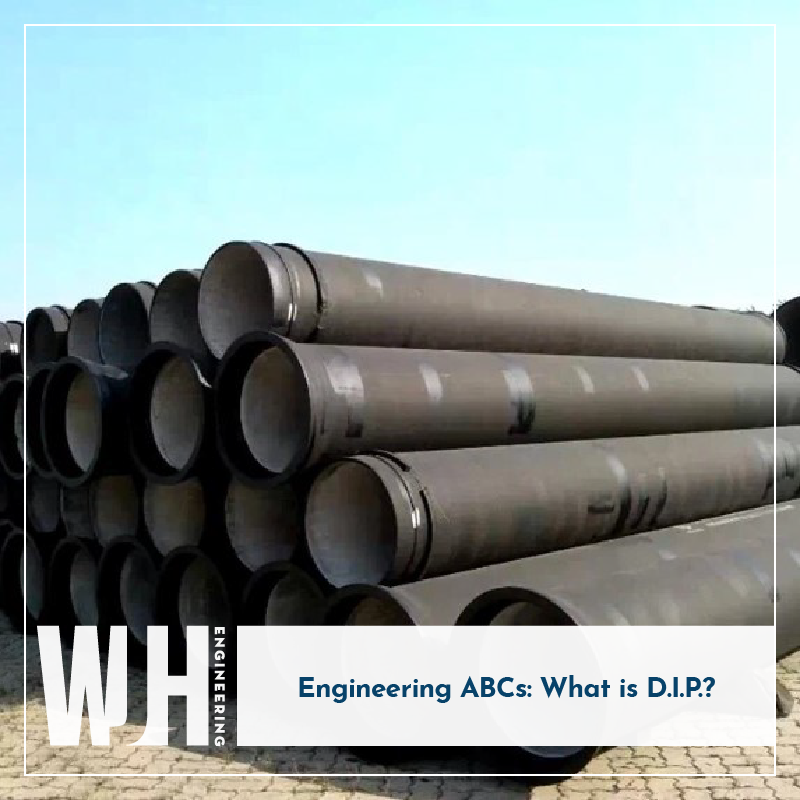

If you’ve spent enough time in this industry, you’ve surely seen the acronym “D.I.P.” before. D.I.P. stands for ductile iron pipe, and it is often used for potable water transmission and distribution. D.I.P. is made of ductile cast iron, which undergoes a unique treatment process that gives it remarkable properties. Unlike traditional cast iron, ductile iron can withstand significant bending and stretching without fracturing, making it highly favorable for various infrastructure applications. It’s also resistant to hazards such as water hammer, frozen ground, heavy traffic, and unstable soils.

One of the primary uses of ductile iron pipe is in water distribution networks, sewage systems, and industrial applications where the conveyance of liquids under pressure is required. The inherent strength of ductile iron allows it to withstand the internal pressures exerted by force mains and industrial piping systems. Additionally, its resistance to external loads, such as soil pressure and traffic loads, makes it ideal for underground installations where it needs to bear substantial weight and stress over time.

Furthermore, ductile iron pipes are preferred for their longevity and corrosion resistance. They are designed with a protective interior lining that prevents corrosion. Sometimes, these pipes are lined with cement on their interior. This added cement prevents corrosion within the pipe to an even further degree, extending its lifespan. The durability of ductile iron pipe is crucial for municipal water supply systems and industrial pipelines, where maintenance and replacement costs are significant considerations. Moreover, ductile iron pipes are easy to install and maintain due to their standardized fittings and joints, which ensure reliable connections and facilitate access for repair work when necessary.

In summary, ductile iron pipe is often utilized for water supply and industrial applications because of its superior strength, flexibility, and durability. These pipes can withstand internal and external pressures, provide long-term corrosion resistance, and are cost-effective over their lifecycle. These characteristics make ductile iron pipes a preferred choice for ensuring reliable and efficient fluid transport in critical infrastructure systems.